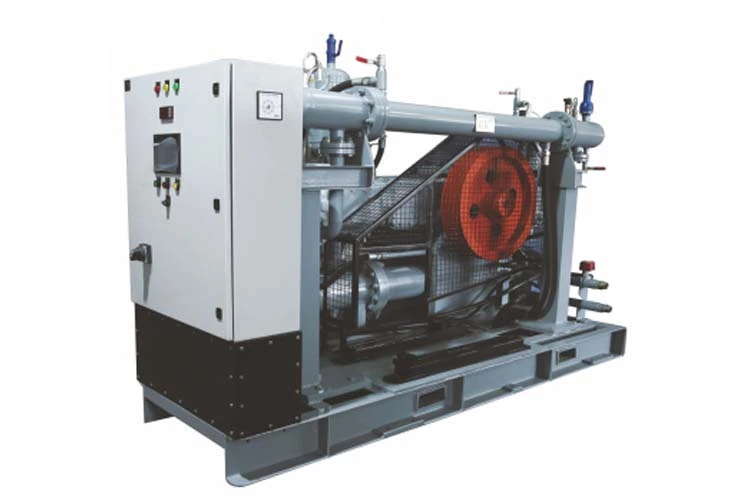

Oil Free High Pressure Reciprocating Air Compressor

- Home »

- Oil Free High Pressure Reciprocating Air Compressor

Buy Oil Free High Pressure Reciprocating Air Compressor

An Oil Free High Pressure Reciprocating Air Compressor is a type of air compressor that operates without the use of oil as a lubricant in the compression chamber. This design ensures that the compressed air produced is free from oil contaminants, making it ideal for applications where clean air is crucial, such as in industries like food processing, pharmaceuticals, and electronics manufacturing.

Colt is the top manufacturer and Supplier of High-Pressure oil Free reciprocating air compressor. The high-pressure capability of our compressor allows it to deliver compressed air at greater pressures, making it suitable for tasks that require significant force or power. The reciprocating action of the compressor's piston allows for efficient compression of air, providing a reliable source of high-pressure air for various industrial operations. Overall, an Oil Free High Pressure Reciprocating Air Compressor is a versatile and efficient tool for applications that demand clean, high-pressure compressed air.

- Available in pressures from 4 bar to 60 bar

- Ideal For Pet Blowing, pharma, food, chemical etc. industries.

- Variable sizes of compressors from 200m 3 / hr to 1700 m 3 / hr

- Wide operation ranges from 400 to 900 rpm

- Robust design

- Vibration free Machines

100 % Oil Free Air:

Oil content in air leads to Contamination of the compressed air system or the final Product. Compressed air from Colt Reciprocating Compressors is free from oil particles thereby Increasing the life of Line Equipment’s, Efficient and wear resistant packing rings isolate oil to the first compartment of the distance piece.

No Foundation Required:

Pre - tested Colt Compressors are free from high vibration levels and hence can be placed on skids. Colt Compressors are equipped with Anti Vibration Mounts which make them the first choice for raised floor installations.

Complete Packaged Solution:

Trouble free installation with Plug & Play type compressors. These are self-contained packages with compressors, radiators, motor, air receiver, dryer and a programmable PLC control system.

Pre - tested for Performance:

Each assembly of every Colt Compressor undergoes careful testing in a state-of-the-art testing Facility. Completely assembled packages are then tested on test beds at variable load settings.

Engineering Excellence:

Highly qualified dedicated engineering project teams provide the most efficient solutions for compression requirements. Regular technological improvements in our product ensure latest offerings for our clients.

Efficient Plate type valves:

World's Most Efficient Hoerbiger Make Valves

• Large flow area

• Special spring protection

• High efficiency and long service life

Cylinders:

• Precision Bored, made of Graded cast-iron

Piston:

• Made of Special high grade aluminium alloy

Crankshaft:

• S. G. Iron crankshaft with large diameters for bearing rigidity with dynamically balanced flywheel for vibration free operation

Piston and Rider Rings:

• Efficient PTFE Piston rings for longer duty cycle in oil free compressors.

• Enhanced working life.

Piston rod and connecting rod:

• Forged and Heat treated followed by precision machining

Distance piece:

• Single Compartment type made of graded cast iron

Touch Screen TFT with PLC:

• 7-inch colour TFT

• Provision for USB data logging

| Model | Cylinder Dimentions mm | Compressor Speed | Working Pressure | Free Air Delivery | ||||||

| Bore | Stroke | RPM | kg/cm2g | m3/min | ||||||

| LP | HP | Min | Max | Min | Max | Min | Max | |||

| HFY | 1HFY28N | 2X185 | - | 115 | 400 | 825 | 1 | 4.5 | 3.27 | 8.8 |

| 1HFY27N | 2X215 | - | 115 | 400 | 825 | 1 | 4.5 | 4.93 | 11.98 | |

| 1HFY25N | 2X250 | - | 115 | 400 | 825 | 1 | 4.5 | 6.89 | 16.11 | |

| HF | 1HF25N | 2X250 | - | 150 | 400 | 900 | 1 | 4 | 9.06 | 23.68 |

| 1HF24N | 2X280 | - | 150 | 400 | 900 | 1 | 3.5 | 11.47 | 29.76 | |

| 1HF23N | 2X310 | - | 150 | 400 | 900 | 1 | 3 | 14.73 | 36.84 | |

| Model | Cylinder Dimentions mm | Compressor Speed | Working Pressure | Free Air Delivery | ||||||

| Bore | Stroke | RPM | kg/cm2g | m3/min | ||||||

| LP | HP | Min | Max | Min | Max | Min | Max | |||

| HFY | 2HFY28N | 185 | 105 | 115 | 400 | 825 | 6 | 8 | 1.92 | 4.04 |

| 2HFY27N | 215 | 140 | 115 | 400 | 825 | 6 | 8 | 2.74 | 5.73 | |

| 2HFY25N | 250 | 140 | 115 | 400 | 825 | 6 | 8 | 3.49 | 7.3 | |

| 2HFY28N | 185 | 105 | 115 | 400 | 825 | 9 | 16 | 1.77 | 3.91 | |

| 2HFY27N | 215 | 140 | 115 | 400 | 825 | 9 | 9.5 | 2.72 | 5.64 | |

| 2HFY25N | 250 | 140 | 115 | 400 | 825 | 9 | 9 | 3.47 | 7.15 | |

| HF | 2HF25N | 250 | 160 | 150 | 400 | 900 | 4 | 8 | 5.15 | 11.82 |

| 2HF24N | 280 | 160 | 150 | 400 | 900 | 4 | 8 | 6.49 | 14.86 | |

| 2HF23N | 310 | 185 | 150 | 400 | 900 | 4 | 8 | 7.79 | 18.22 | |

| Model | Cylinder Dimentions mm | Compressor Speed | Working Pressure | Free Air Delivery | ||||||

| Stroke | RPM | kg/cm3g | m3/min | |||||||

| Min | Max | Min | Max | Min | Max | |||||

| HF | 3HF25N | 150 | 400 | 750 | 16 | 40 | 2.7 | 8 | ||

| 3HF24N | 150 | 400 | 750 | 16 | 40 | 5.5 | 10.3 | |||

| 2HF23N | 150 | 400 | 750 | 16 | 40 | 2.9 | 5.6 | |||

| 3HF4N | 150 | 400 | 750 | 16 | 40 | 7.1 | 16 | |||

| 3HF44N | 150 | 400 | 750 | 16 | 40 | 8.4 | 16 | |||

| 3HF43N | 150 | 400 | 750 | 16 | 40 | 13.3 | 25.7 | |||

|

Model

|

Cylinder Dimentions mm | Compressor Speed | Working Pressure | Free Air Delivery | ||||||

| Stroke | RPM | kg/cm3g | m3/min | |||||||

| Min | Max | Min | Max | Min | Max | |||||

| HF | 4HF43N | 150 | 400 | 750 | 30 | 120 | 3.6 | 6.6 | ||

| 4HF44N | 150 | 400 | 750 | 30 | 120 | 5.3 | 10 | |||

| 4HF45N | 150 | 400 | 750 | 30 | 120 | 6.4 | 12 | |||

| 4HF42N | 150 | 400 | 750 | 30 | 120 | 11.6 | 17.5 | |||

| 4HF41N | 150 | 400 | 750 | 30 | 120 | 13.3 | 22 | |||

| 4HF43N | 150 | 400 | 750 | 30 | 120 | 7.4 | 14

|

|||